Hallam is helping to create a modular AC powered LED (no driver required) with an integrated specially developed hardwired PCB. This will significantly reduce weight and complexity and hence improve installation time and in-service life. A sealed explosion proof lens will enable the LED units to be used in hazardous and confined spaces.

Customers will benefit from substantial cost savings through lower energy costs by switching to this LED configuration, the longer lifespan of an AC LED providing payback within 12 months. In addition the modular nature of the system means that 60W modules can be combined (1,2,4,6,8,9) to create a bespoke system that provides the exact illumination required for site, space or work activity, without wasting power and substantially reducing energy consumption.

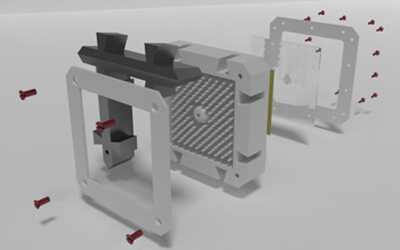

Hallam has been extensively involved in the design and prototyping of the LED board housing and heatsink (including thermal transfer calculations) and housing connectors. These designs were crucial in achieving the modularity required.