Hallam has acquired a Frech DAK 580 diecasting machine from Germany to further enhance an impressive array of diecasting equipment. The foundry division now has the capability of manufacturing an even wider range of aluminium castings, by weight and complexity. As a guide, the new machine can make castings weighing up to 8kg and 60cm in diameter, and is the largest machine in the Hallam’s portfolio, which now includes a total of 6 Frech machines ranging from 210 to 580 tons locking force.

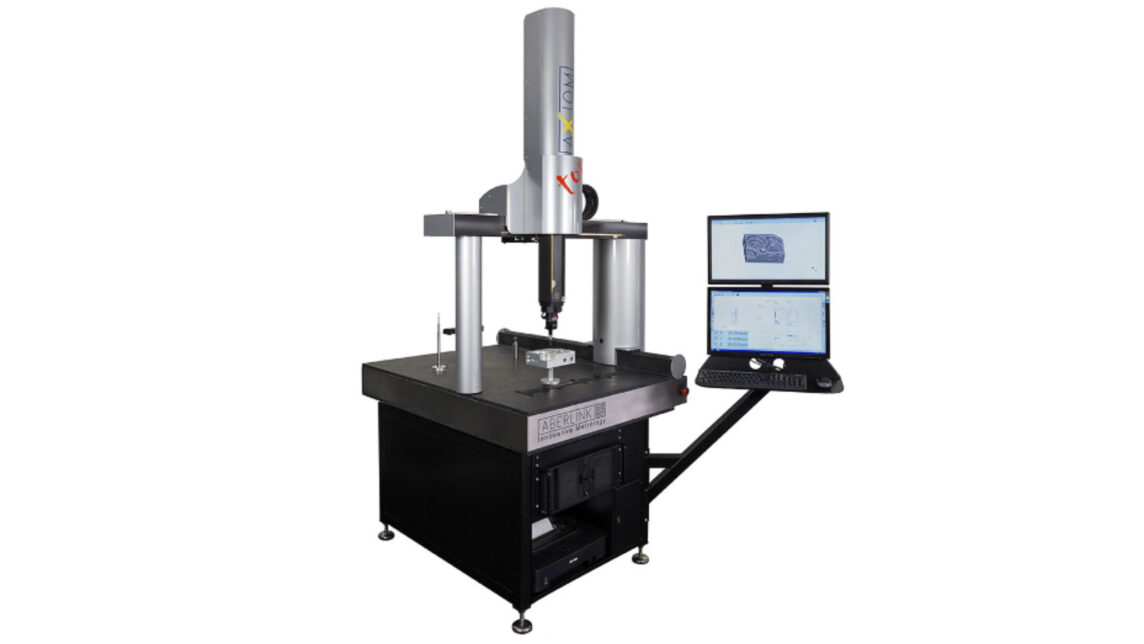

Hallam purchase Axiom too 600 CNC Co-ordinate Measuring Machine (CMM)

In January 2021 Hallam took delivery of a British-made Aberlink Axiom too 600 CNC CMM. Fast, accurate and reliable, the Axiom too is a fully motorized moving bridge type CMM with Aberlink 3D geometric measurement software for CNC applications, providing a genuine graphical interface.

The Axiom CMM allows measurement requirements to be undertaken efficiently and speedily. Each component is placed in a purpose-made fixture on the bed of the CMM and measurements at different points on the component are taken automatically by the machine. The machine is housed within a Kaiser + Kraft (UK) Limited modular inspection office on the shop floor next to the CNC machining centre.

This initiative follows Hallam winning new contracts to develop and supply product in volume to a major UK-based electric vehicle manufacturer, where PPAP techniques must be deployed. Further contracts (generating higher volumes and additional jobs) depend specifically on productivity improvements in component measurement for statistical process control. The CMM also improves efficiency where sampling techniques are employed for process capability assessment (e.g. Cpk).

The improvement in throughput rate arises from the programmability of the machine, allowing the storage and recall of measurement instructions for specific components and products, and from the motorisation of the sensor head permitting rapid movement to the reading points. The system also interacts fully with CAD systems including the Solidworks Professional and Camworks software used by Hallam. Measurement instructions can be specified via these links: a CAD model for the component or product being measured can be recalled and measurement points specified via a graphical link to the model.

Hallam MD appears in MAKE UK’s “Levelling Up” seminar

Hallam’s Managing Director Rob Pickersgill was invited to join the panel of MAKE UK’s “Levelling Up” webinar on 26th November discussing MAKE’s report on regional disparities in manufacturing in the UK. The panel consisted of Rob plus:

Ed Miliband, Shadow Secretary of State for Business, Energy and Industrial Strategy

Steve Fogg, Chair of the Lancashire Enterprise Partnership and NP11 Innovation Lead

Neil Sevitt, Partner and Head of Manufacturing for Yorkshire and North East Region, RSM

MAKE’s report identifies significant differences in productivity and income per head across the regions and the panel answered questions from the large webinar audience about how these differences should be addressed, including the role of general infrastructure spending in the levelling-up process. The importance of devolution of spending powers to Mayoral Authorities and LEPs for local infrastructure spending and business support was also emphasized. Ed Miliband pointed out that the Government’s Industrial Strategy Report had given a commitment of support to the regions but in many cases, funding had not yet materialised. Rob pointed out that funding support for manufacturers seeking to increase their productivity was also required.

MAKE UK’s “Levelling Up” webinar

Vimpex visit W. Hallam Castings Factory

In November Vimpex Managing Director, James Jones, and Marketing Director, Charlotte Eames visited Hallam to see the production of alarm system products commissioned during the summer. Vimpex is a highly regarded major specialist UK supplier of technical rescue products and PPE safety equipment designed for emergency services teams.

Vimpex MD James said “We are in great hands with these guys. Each element – gong performance, consistency of output and aesthetics are monitored and controlled by Hallam’s attention to detail and their very long experience of aluminium casting. The ClamBell is a genuinely U.K. manufactured product and will be ready for sale to our European and Worldwide customers. The Bell is dead, gong live the (Clam)Bell!”.

It was an interesting day for both Vimpex and Hallam, as Hallam Operations Director, Colin Woodruff, explained the entire process of manufacturing the aluminium bell gong to James and Charlotte.

Hallam MD Rob Pickersgill said “It was great to welcome the team from Vimpex – our staff thoroughly enjoyed the day. Hallam is proud to be part of Vimpex’s manufacturing supply chain and we are currently working on developing the powder coating finish to achieve something really outstanding”.

Thank you for a great day to James and Charlotte and Hallam looks forward to seeing you again soon.

Hallam MD joins “Make UK” Regional Advisory Board

Hallam MD Rob Pickersgill has been invited to join the “Make UK” Regional Advisory Board for the Yorkshire and Humberside area. The Board holds regular meetings and takes part in online meetings with MPs as part of the lobbying process for support for UK manufacturing. Rob commented “Make has excellent professional staff and produces really authoritative analyses of UK manufacturing activity and needs. It is also involved in high level lobbying at Westminster. I’m very happy to have been invited to become involved in supporting these activities”.

Make UK is currently highlighting issues around support for UK manufacturers during the Covid pandemic, the manufacturing skills shortage, funding for investment and the implications for international trade of Covid and the end of Brexit transition period, as well as green initiatives including decarbonization for manufacturing processes. Rob has already been involved with other leading South Yorkshire manufacturers in virtual meetings with MPs responsible for advising on Government policy in these areas.

Hallam Featured on ITV Calendar News

Regional ITV news has featured Hallam in a TV news item around the effects of lockdown on businesses in the “Calendar News” area. The news item included a tour of Hallam’s facilities including pressure casting, CNC machining and powder coating facilities, as well as interviews with staff explaining how they had coped with having to work through lockdown (because of Hallam’s “essential supplier” status) and what their hopes for the future were.

“The Calendar piece was very professionally produced” said MD Rob Pickersgill – “but I wish that we could have emphasised more how hard our people have worked through an incredibly difficult period, and how grateful the company is for their efforts. We may get another chance as I understand that ITV is planning a dedicated feature around manufacturers in our area coping with the pandemic. Manufacturing is particularly important for the Yorkshire and Humberside region as more than 300,000 people are employed in the sector. Companies are heavily dependent on exports to the EU, so Brexit also is a key issue for the region”.

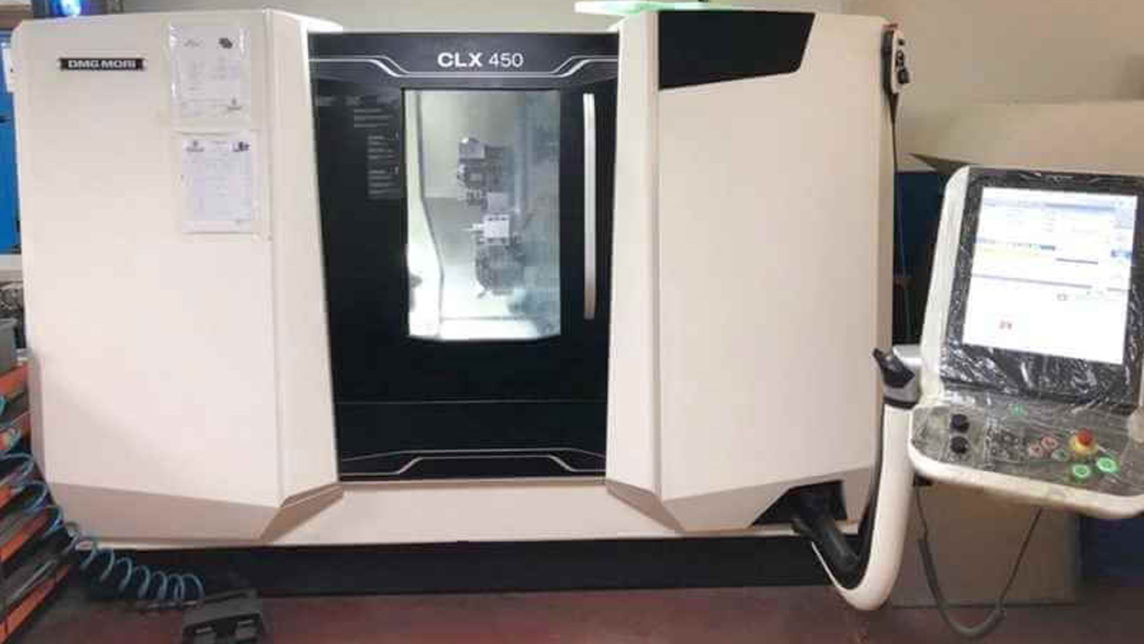

DMG Mori CLX 450 for Hallam

Hallam is continuing to invest in leading edge CNC technology with the acquisition of a new DMG Mori CLX 450 V4 turning centre to extend the capability of the machining unit. The 450 will be delivered in January 2020 and installed alongside two Mori CMX 800V vertical machine centres purchased new in 2019.

Simplicity and speed in setting up the machine for a wide range of tasks was a major consideration for Hallam and the Fanuc controls allow easy programming of the Y axis and live driven tooling with C axis, providing complex turning capability. The verification and graphics checks ensure a reliable milling and turning toolpath.

The machine removes the need for turning and milling operations on different machines and many components will be completed in one hit. As well as manufacturing parts around 20% quicker, Hallam will save handling and setting costs, and fixtures for different operations will largely be eliminated.

Hallam Offers State of-the-art architectural powder coating system

Independent trials have confirmed that Hallam can now offer market leading powder coating with powders that have significantly longer gloss retention and resistance to colour change combined with maximum film integrity to ensure long term cosmetic and functional protection.

The trials were undertaken in accordance with ISO 4892-3 and ASTM G154 by an independent professional testing house and simulated 10 years exposure to Caribbean sunshine. The test report conclusions were that “the exposure to UV radiation had no noticeable effects on the colouring or surface finish of the components”.

Products powder coated using the system are now available commercially from Hallam. Please contact Rob Pickersgill, 07720591991 anytime, for full details.

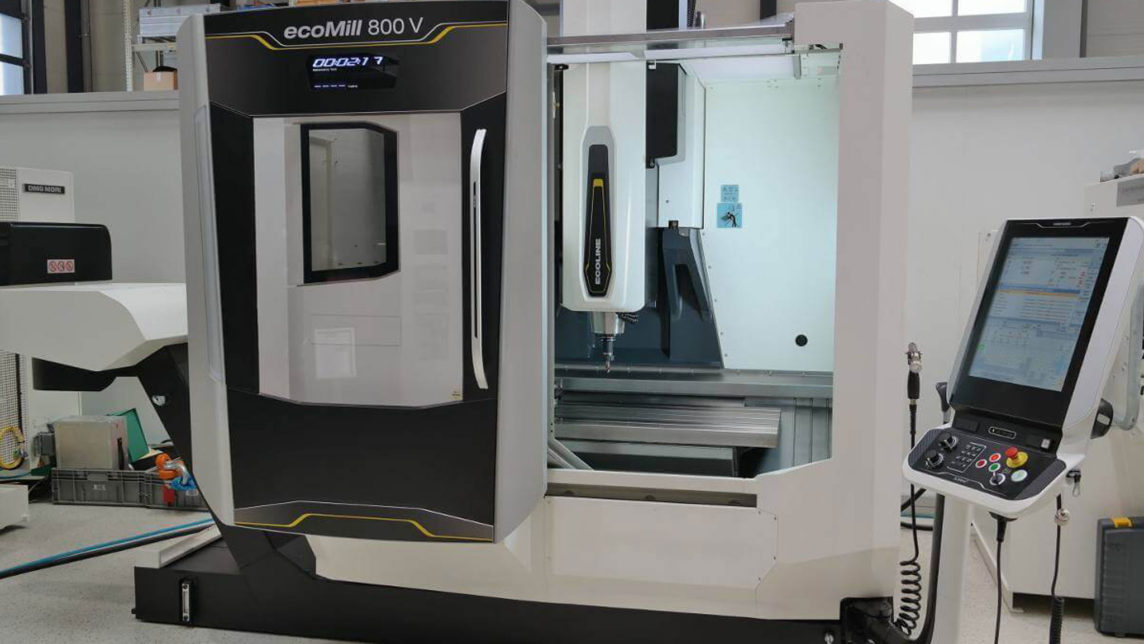

Additional new DMG VMC for Hallam

Hallam’ s quest to implement state-of-the-art technology in all manufacturing process areas continued with the installation in April of a further DMG Mori CMX 800V vertical machine centre, primarily for use within the machining operations unit. This follows the acquisition of a further Frech DAK 350 diecasting machine in December 2018, creating substantial additional capacity across common technological platforms within the two process areas.

MD Rob Pickersgill explained; “We are standardising on Frech diecasting and DMG Mori machining equipment so that the maintenance overhead is manageable. The main consideration however is the outstanding quality of the two platforms, which has already driven our ISO 9001 BSI Quality KPIs to levels much better than target. As a consequence capacity, turnover and margins are all now much improved, and will continue to do so. We have ambitious plans for the future.”

MD Rob Pickersgill explained; “We are standardising on Frech diecasting and DMG Mori machining equipment so that the maintenance overhead is manageable. The main consideration however is the outstanding quality of the two platforms, which has already driven our ISO 9001 BSI Quality KPIs to levels much better than target. As a consequence capacity, turnover and margins are all now much improved, and will continue to do so. We have ambitious plans for the future.”

Hallam Apprentice progresses to Degree-level course with AMRC

Hallam uses state-of-the-art CNC machinery in its foundry, machining centre and powder coating factory and apprentices trained at the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) are a key element of the workforce needed to work with this type of equipment.

Recruitment is facilitated by the AMRC, which invites applications from prospective apprentices and helps to evaluate and screen applicants on behalf of employers. This service in its own right is enormously helpful for employers. Selected apprentices are then trained jointly at the AMRC and employer’s premises and should achieve the EAL level 3 extended diploma and BTEC level 3 diploma in engineering within 3 years. EAL is part of Semta – the Science, Engineering, Manufacturing and Technologies Alliance – which is a not-for-profit organisation responsible for engineering skills for the future of the UK’s most advanced sectors.

AMRC Apprentices are now able to progress to University of Sheffield foundation degree level within a further 2 4 months and achieve the University’s Bachelor of Science in Engineering within a further 20 months. Hallam has three apprentices in training at the AMRC currently, one of whom is now progressing to full degree level.

Two of the three were nominated for the AMRC’s “Apprentice of the Year” awards in 2017 and 2018, competing against apprentices from Rolls Royce and Siemens, and one was successful in achieving an award.

Hallam intends to continue to train all its employees at the AMRC as the basis of its skills updating and succession planning and is currently recruiting a further two apprentices for the March 2019 intake.