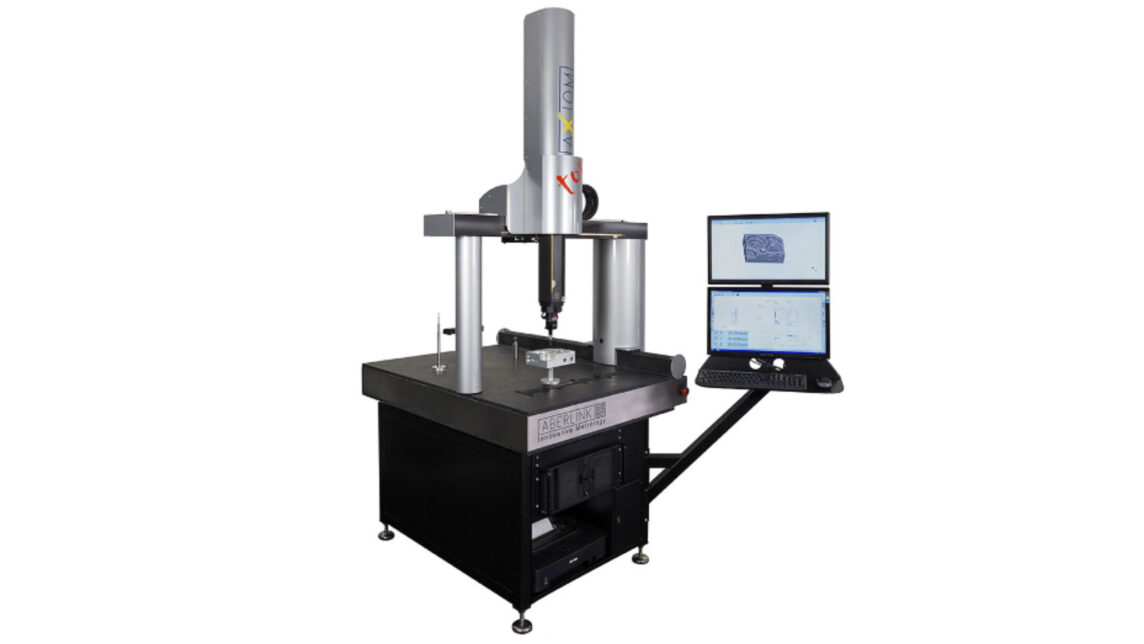

In January 2021 Hallam took delivery of a British-made Aberlink Axiom too 600 CNC CMM. Fast, accurate and reliable, the Axiom too is a fully motorized moving bridge type CMM with Aberlink 3D geometric measurement software for CNC applications, providing a genuine graphical interface.

The Axiom CMM allows measurement requirements to be undertaken efficiently and speedily. Each component is placed in a purpose-made fixture on the bed of the CMM and measurements at different points on the component are taken automatically by the machine. The machine is housed within a Kaiser + Kraft (UK) Limited modular inspection office on the shop floor next to the CNC machining centre.

This initiative follows Hallam winning new contracts to develop and supply product in volume to a major UK-based electric vehicle manufacturer, where PPAP techniques must be deployed. Further contracts (generating higher volumes and additional jobs) depend specifically on productivity improvements in component measurement for statistical process control. The CMM also improves efficiency where sampling techniques are employed for process capability assessment (e.g. Cpk).

The improvement in throughput rate arises from the programmability of the machine, allowing the storage and recall of measurement instructions for specific components and products, and from the motorisation of the sensor head permitting rapid movement to the reading points. The system also interacts fully with CAD systems including the Solidworks Professional and Camworks software used by Hallam. Measurement instructions can be specified via these links: a CAD model for the component or product being measured can be recalled and measurement points specified via a graphical link to the model.