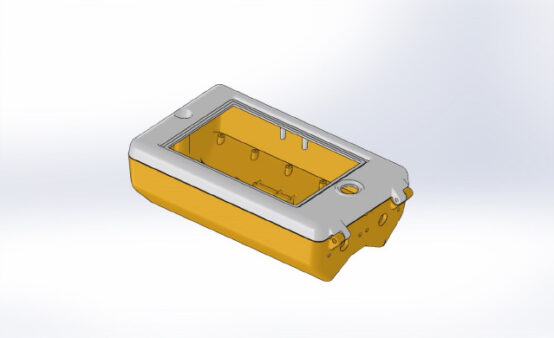

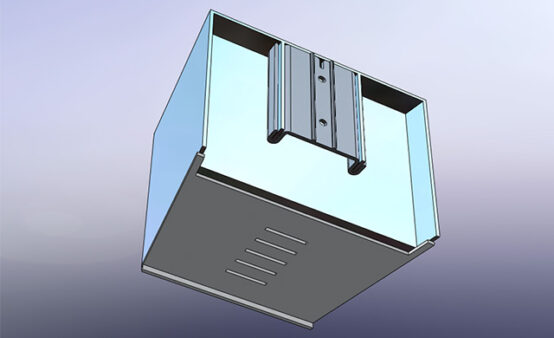

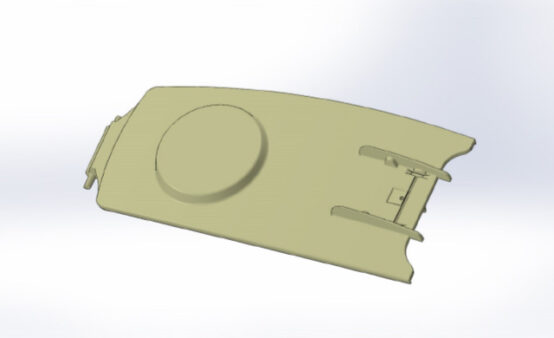

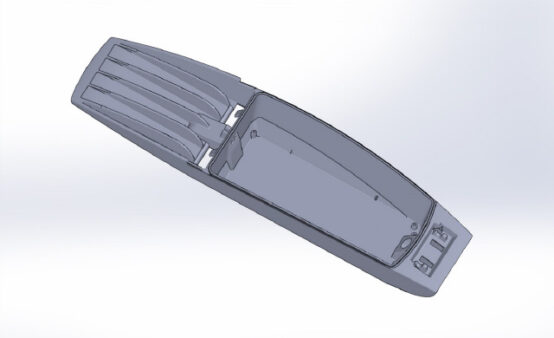

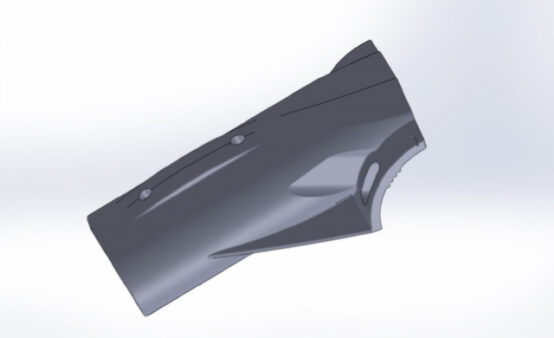

Hallam Castings product prototype development team has helped to design, prototype and develop new products ranging from flat screen arms and an encrypted computer hard disc drive to animal ear taggers and a motorised hospital patient trolley as well as a wide range of original die cast components for established products.

Hallam Castings product prototype design team uses leading edge computer technology to develop prototypes and works closely on design issues with the University of Sheffield via its Knowledge Transfer Partnership (KTP) Agreement and the Advanced Manufacturing Research Centre (AMRC), which provides highly sophisticated simulation and testing facilities under the terms of a further Partnership Agreement.

Take a look at some of our recent Prototype Productions…

Contact us to learn more about how we can help with your Prototype Production…

Concept to Completion

Hallam Castings can work on product prototype projects at the concept stage, and our involvement has led to the development of strong links with customers who now trust and rely on Hallam castings to provide a wide range of prototype development and product design solutions.

Recent product prototype development projects include the safety light developed for the London underground system, and a new LED based floodlighting system for industrial and commercial use.

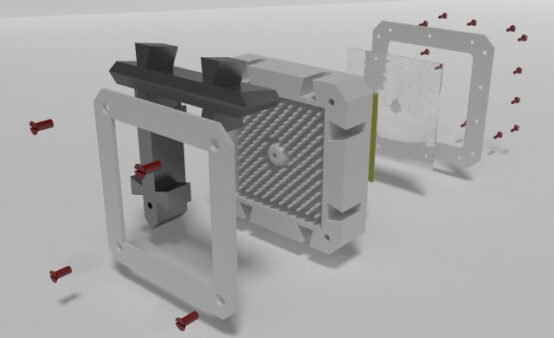

Hallam Castings expertise in component assembly also provides customers with valuable feedback when product prototype components are being tested and assessed from an assembly perspective, and leads to the emergence of efficient assembly regimes.

Prototyping Techniques

Hallam Castings can create machined product prototypes quickly from CAD models linking via CAMWORKS to the company’s CNC machining centres – i.e. using “subtractive” processes.

Hallam Castings can also offer other product prototype techniques including Stereolithography, Selective Laser Sintering and 3D printing – “additive” techniques – through its links to the Advanced Manufacturing Research Centre and the Mercury Centre, both within the University of Sheffield.

Hallam Castings also uses sand and investment casting, laser cutting and fabrication techniques within product prototype projects.

As well as iterative form, fit and function testing within the prototyping cycle Hallam Castings is also able to develop special aluminium and zinc alloys to provide exceptional mechanical properties or corrosion resistance within components or products. Finite element analysis can be provided on CAD models.

Case studies

If you would like to view any of our case studies click below.