Hallam MD Rob Pickersgill is discussing plans to construct a new state-of-the-art 5,000 square feet factory unit on a “green field” section of Hallam’s 2.2 acre industrial site with Doncaster MBC.

The project depends partly on the completion of supply contract agreements with a highly prestigious UK OEM and also with a large European Manufacturer.

‘The new factory would be capable of operating to automotive, aerospace and even medical equipment quality standards, and is being enthusiastically supported from all sides’ said Rob.

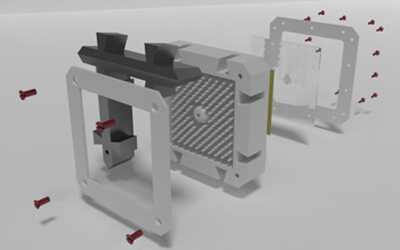

Hallam has the ISO 9001:2015 standard (BSI) at present and the factory would have machinery utilising the very latest robotic technologies operated by staff trained at the Advanced Manufacturing Research Centre in Sheffield. Hallam has five apprentices training at the AMRC at present.

‘Low cost labour countries are still a major threat to UK manufacturers. Installation of the latest manufacturing technologies and staying up-to-date is the only sustainable defence. Hallam staff are familiar with the “Factory of the Future” at the AMRC site, which provides the vision for this development’ added Rob.